Chimney 101: Diagrams & Glossary of Terms

All About Chimneys: Chimney Diagram

& Glossary of Terms

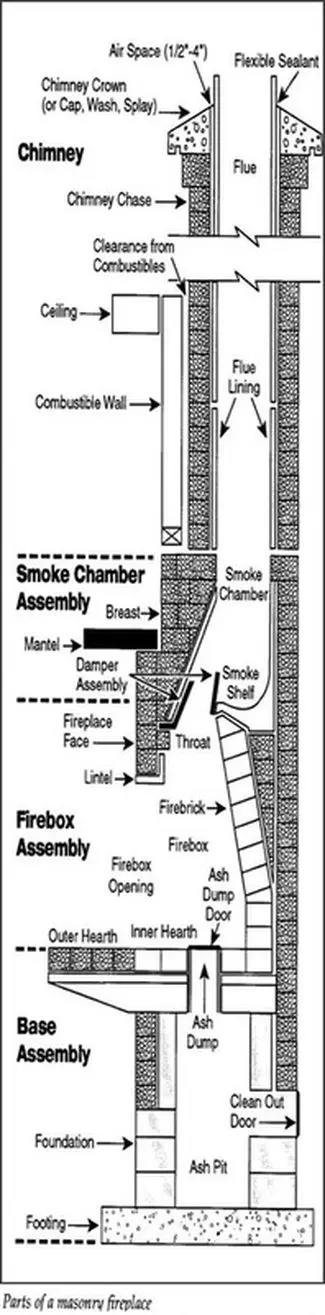

Anatomy of a Masonry Chimney

- Chimney Cap (not shown in this illustration): Chimney caps cover the top opening of the flue for the purpose of keeping out rain and snow. Moisture is the number one cause of chimney and fireplace deterioration. The chimney cap is also a spark arrestor, which keeps sparks and cinders from landing on the roof. Chimney caps also keep out animals, leaves, and other debris.

- Chimney Crown (wash or splay): The chimney crown is the cast concrete or mortar splay at the top of the chimney that seals off the air space between the outer walls of the masonry chimney and the flue liner and prevents water entry into the stack. The cement crown slopes away from the flue to wash the water away. There should be a flexible, non-combustible expansion joint between the flue liner and the crow to allow for thermal expansion and prevent the flue tiles and/or crown from cracking.

- Flue: A safe pathway for heat and combustion by-products through the construction of the home, otherwise known as the interior walls of the chimney.

- Chimney Liner: The safe, approved material that lines the flue’s interior. This material should be 5/8″ or thicker terracotta tiles or a UL-listed liner made of stainless steel or other approved materials.

- Chimney: The structure that passes through the construction of the home and encloses the flue (or flues).

- Smoke Chamber: The dome area of brick corbels that supports the flue tiles and directs flue gases safely to the flue. This area should be parge coated with super cement to provide a smooth transition to the flue (draft performance), protect the masonry, and prevent cinders, heat/fire, and carbon monoxide from entering the home through voids in otherwise exposed brick and mortar.

- Smoke Shelf: The area located behind the damper that prevents down drafts from coming into the firebox area and home. This throat design also increases the velocity of the flue gasses, which helps draft performance.

- Damper: The damper closes off the fireplace from the outside of the house. This is what prevents air loss from your home when the fireplace is not in use. In some cases, the damper can be used to regulate the chimney’s draft.

- Mantel: This is typically a decorative shelf above a fireplace. It may also be a beam, stone, or arch that serves to support the masonry above the fireplace.

- Lintel: The horizontal architectural member or header above the fireplace opening that provides support for the brickwork above the fireplace opening.

- Fire Brick: Heat-resistant brick that lines the firebox or combustion area of a fireplace, stove, boiler, or furnace.

- Ash Dump: An opening located in the inner hearth of some fireplaces, which leads to an ash pit for convenient ash removal and fireplace cleaning.

- Ash Pit: A cavity underneath a fireplace firebox used as a receptacle for ashes and is accessible for clean-out by way of a clean-out door located outside the home or, in some cases, in a basement.

- Firebox: This is where you build the fire, also known as the interior of the fireplace.

- Inner Hearth: The floor of the fireplace, inside the opening.

- Outer Hearth or Hearth Extension: This is the technical term for what is usually referred to as the hearth. It is the non-combustible floor area in front of the fireplace that is required for safety. NFPA code requires the outer hearth to extend 18″ from the fireplace opening.

- Top-Sealing Damper: Also known as a chimney top damper. A damper mounted at the top of the flue is used as an alternative to a throat damper and is also an energy-saving device.

Typical Factory-Built Zero Clearance

Chimney & Fireplace

- Termination Cap or Chimney Cap: The last piece of the topmost part of a factory-built chimney pipe system, which serves the purpose of arresting sparks, keeping water out of the flue, and providing an outlet for cooling air on an air-cooled chimney system.

- Chase Cover (bottom pan): A custom-made flashing that keeps water out of the chimney chase and home while providing an opening for the pipe termination.

- Chase: A pathway for a manufactured chimney pipe to pass through. Chases are commonly built on the home to resemble a traditional chimney, to provide lateral support for the chimney pipe, and to keep the cold weather from cooling the flue.

- Firestop/Firestop Spacer: A manufactured component of a factory-built chimney that separates the fireplace enclosure from attic areas or other levels of the home and assures proper heat clearances to adjacent combustibles. This slows the spread of fire through a home in the instance of a house fire and is required by building code and hearth system manufacturers.

- Chimney Pipe: The listed venting that passes through the construction of the home, which ensures heat and flue gasses are terminated to the home exterior. The manufacturer of the hearth appliance determines the type, size, and, in most cases, the brand/model of chimney pipe that must be used.

- Fireplace: This is the firebox or place where you build the fire or place the gas logs.

- Hearth Extension: The non-combustible floor area in front of the fireplace that is required for safety. NFPA code requires the outer hearth to extend 18″ from the fireplace opening. Technically, the “hearth” of a fireplace is the floor of the fireplace where combustion occurs during operation.

Class A Chimney System

- Class A Chimney Pipe: High-temperature, generally pack-insulated, multi-layered pipe that has undergone rigorous UL testing standards by being heated to 2100 degrees F three times. This chimney pipe is used to vent solid fuel-burning appliances like wood and coal stoves, furnaces, and EPA Phase II-certified fireplaces and stoves. Class A chimney pipe is listed as UL 103HT in the USA and ULC S-629 in Canada.

- Storm Collar: Metal band around the pipe, above the flashing, that prevents water from entering between the pipe and flashing.

- Roof Flashing: Sheet metal component typically with a flat base that seals the penetration in the roof where the pipe passes through.

- Attic Insulation Shield/Attic Radiation Shield: Chimney component that prevents insulation from being blown against the pipe and assures the pipe’s heat clearance requirements.

- Ceiling Support Box/Chimney Support: Generally, the first piece of chimney that is fastened to the framing of the house and supports the entire weight of the chimney system. The bottom side often has a decorative collar and is exposed in the home’s interior.

- Chimney Connector/Stove Pipe: Single or double wall pipe that connects a solid fuel appliance to its chimney system. The chimney connector is available in single-wall or double-wall pipe. It is important to select the proper pipe with respect to the clearance requirements for the wall, which are determined by the manufacturer in testing or NFPA 211.